Cert(ification): the Four-Letter Word

To aircraft manufacturers, CERT(ification) feels like a four-letter word.

Headlines of delayed entry into service and cost overruns make certification feel like a roll of the dice where the whim of a regulator undoes years of engineering.

Nothing could be farther from the truth.

The path to certification is highly structured and mapped out*:

1️⃣ PRE-APPLICATION | Alignment on the concept, novel conditions, and issue papers

2️⃣ CERTIFICATION BASIS | Agreement on regulation applicability, and showing compliance

3️⃣ DESIGN & ANALYSIS | The bulk of engineering work (detailed modeling, safety analysis)

4️⃣ VERIFICATION | Test and documentation (material qualification, ground tests)

5️⃣ FLIGHT TEST | The visible capstone, but just one step in a long chain of events

6️⃣ TYPE CERTIFICATE 🏆 | Confirmation by the regulator that the design complies

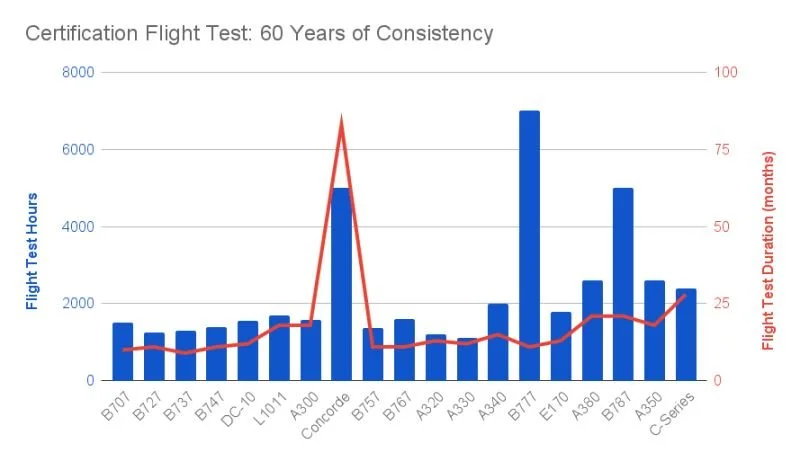

👉🏼 Once an aircraft actually makes it to flight test – the part often shown in the media – the process has been remarkably consistent despite more than 130 updates to the regulations since 1964.** Excluding Concorde, clean-sheet programs cluster around ~1,900 flight hours over ~15 months.***

When programs slip years behind schedule, it is NOT because the regulator “moved the goalposts” during flight testing. It slipped because the engineering in steps 3 & 4 wasn’t ready.

The real challenge is that conventional aircraft architectures make steps 3 & 4 harder with every generation. As systems get more tightly coupled, proving compliance becomes exponentially more complex. For novel aircraft like eVTOLs, even steps 1 & 2 can add years.

✈️ What we need are architectures that manage complexity instead of compounding it. That’s why we’re so focused on modularity: it lets us build on existing certification bases while decoupling systems, giving us many more pathways to demonstrate compliance without delaying schedules.

🔎 Achieving Type Certification is only half the battle; manufacturers must also earn a Production Certification to prove that they can consistently build conforming aircraft. In our next posts, we’ll preview this side of certification and why it’s equally critical.

__

Sources

* See FAA Order 8110.4 for the specifics

** Link

*** Aggregated from wikipedia and other similar sources